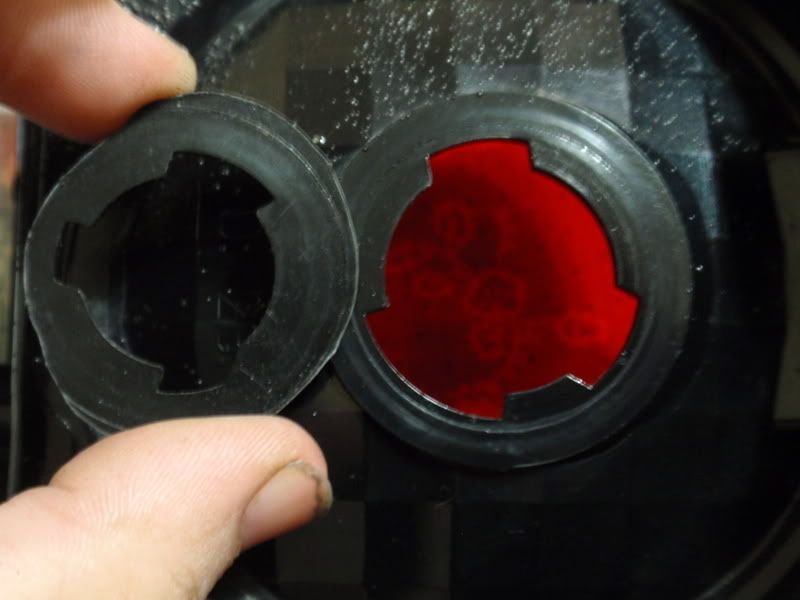

Later, I retrofitted a set of factory bulb holders onto the L1224R's by cutting off the LED's "twist knobs", cutting apart the bulb holder so it would fit perfectly onto the LED with a little gap below for the rubber sealing ring. Scuffed the outer surface of the LED and the inner of the new parts and used JB weld. This put the LED more into the housing, thus utilizing the reflector better.....made the light output better and it better filled the round reflector to bounce light off the entire reflector.

There are different types of those bulb holders that will screw into the Ranger Tail/Brake/Turn holder. Some that are more streamlined while others are more bulky....and if memory serves me correctly, one is more desirable than the other for this particular job.

You seem very detail oriented judging by how your truck is progressing, something to keep in mind is the orientation of the LED pigtail. In certain areas, it will hit your bed sheet metal or the lamp won't even install. Test fitting is the best thing to do before putting the "permanent" epoxy or JB weld onto the parts. When I retrofitted, you've got two variables now so keep that in mind.

Pictured below is how mine are oriented to the lamp....great clearance from the body panels and screws.

Unfortunately back when I retrofitted sometime in 2011, I never took pics of the process. I will be back with my truck on Monday night and will update this thread with pictures if you'd like. As well as pictures of the different bulb holders.

You will need to get an LED rated EP27 flasher to eliminate "hyperflash"....when the blinkers blink like crazy because they think a bulb is out.

They've worked absolutely flawlessly for the last 5+ years and expect them to last 5+ more! Thanks for the link!!! I'm thinking about splurging on another set to let my Electrical Engineer little brother tinker with them for use up front...in AMBER.