You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shane, Hurst vent question.

- Thread starter 01B3000

- Start date

Fx4wannabe01

New Member

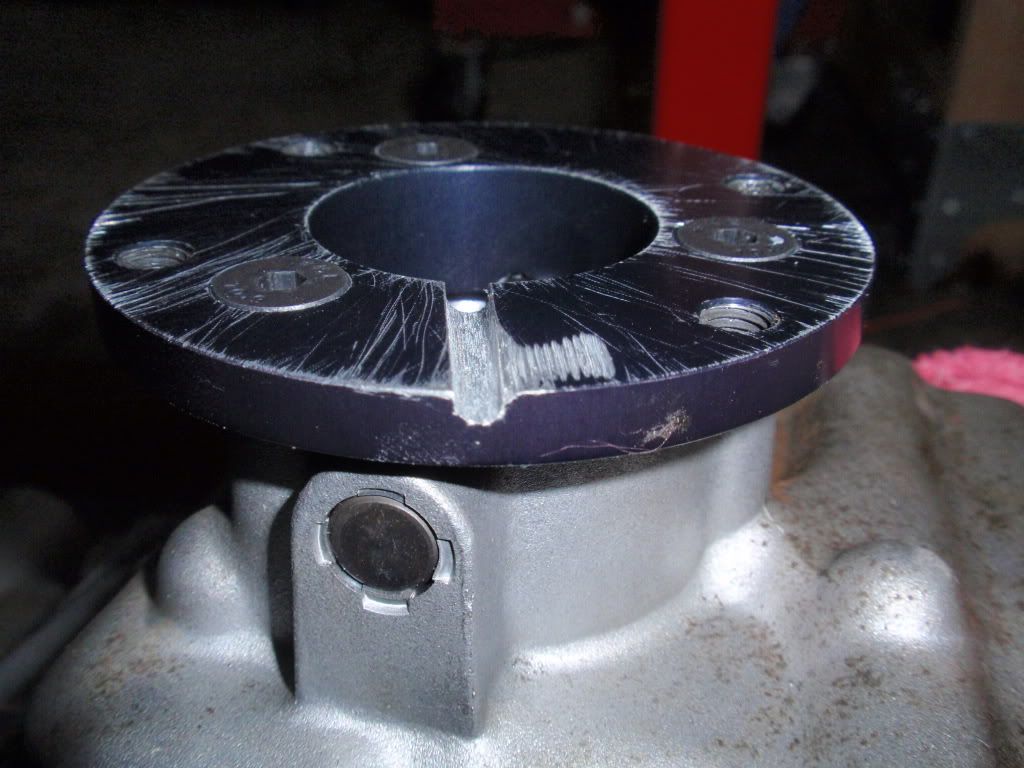

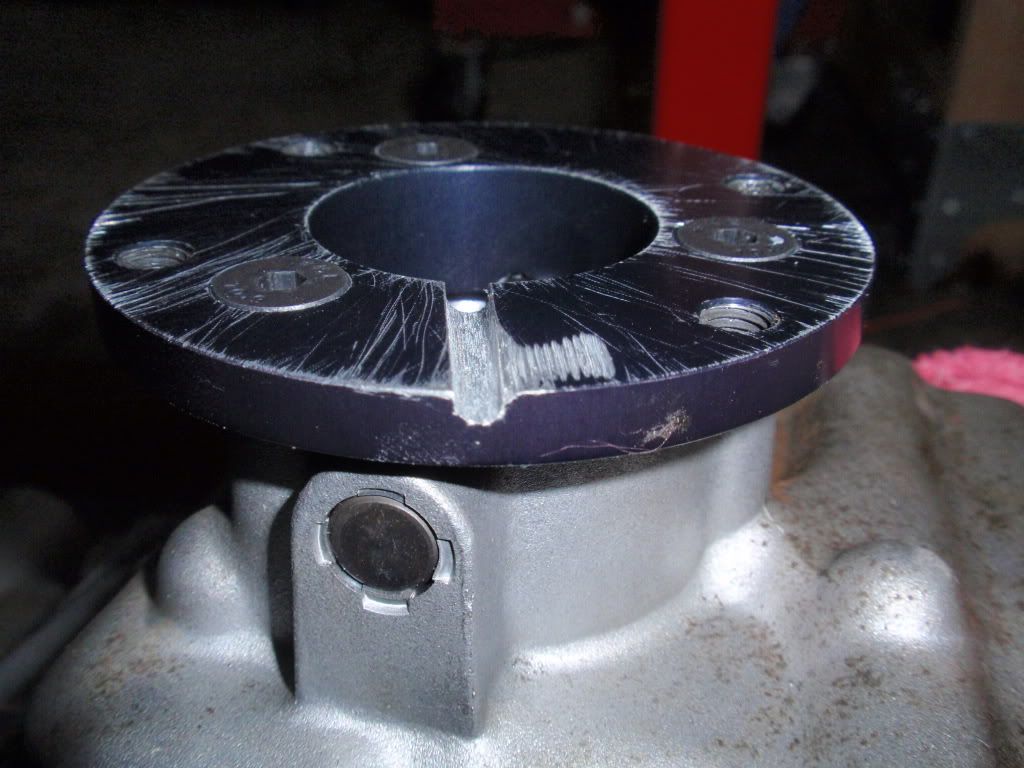

Holding up very well after almost 2 years of this notch. I've done every Hurst vent fix out there up until I stumbled upon my brain coming up with this. lol. I don't go on any other forums so you'll have to settle for this...

During my last trans replacement, I prepped for a vent tube up to the engine bay, but left it plugged off due to me being cheap and not buying hose. lol. While that was happening, I pondered this idea and did it. I basically made a Hurst version of the stock shifter vent.....grinder groove. Next time it's out, I plan on adding another groove or widening the groove. Top tip: Make your groove be on the passenger side of the trans. This lessons the chance of oil being thrown at it due to rotation. Might be a moot point, but whatever.

I used a thin layer of grey silicone to replace the hurst rubber gasket that goes to hell within a couple turns of the mounting bolts. Be sure to keep the groove clean of silicone...you don't want to plug it up.

No leaks coming from the top of the trans anymore. I do have a current issue of my tailhousing to trans case silicone not holding up well, or it's a bad trans output seal(more likely). Whatever it is, it's driving me nuts having an oily tcase skid. lol.

Any other questions, don't hesitate to ask!

During my last trans replacement, I prepped for a vent tube up to the engine bay, but left it plugged off due to me being cheap and not buying hose. lol. While that was happening, I pondered this idea and did it. I basically made a Hurst version of the stock shifter vent.....grinder groove. Next time it's out, I plan on adding another groove or widening the groove. Top tip: Make your groove be on the passenger side of the trans. This lessons the chance of oil being thrown at it due to rotation. Might be a moot point, but whatever.

I used a thin layer of grey silicone to replace the hurst rubber gasket that goes to hell within a couple turns of the mounting bolts. Be sure to keep the groove clean of silicone...you don't want to plug it up.

No leaks coming from the top of the trans anymore. I do have a current issue of my tailhousing to trans case silicone not holding up well, or it's a bad trans output seal(more likely). Whatever it is, it's driving me nuts having an oily tcase skid. lol.

Any other questions, don't hesitate to ask!

SalRanger2

Ranger Lover

check this out, i believe this is what you were talking about this way right?

http://www.fordrangerforum.com/drivetrain-tech/51445-hurst-shifter-owners-issue-found.html

this is the only way id do it if i got one, just seems like alot of dickin around for me ha..

http://www.fordrangerforum.com/drivetrain-tech/51445-hurst-shifter-owners-issue-found.html

this is the only way id do it if i got one, just seems like alot of dickin around for me ha..

Fx4wannabe01

New Member

I guess theres no chance of Hurst Fixing this issue from the factory. I decided to turn away from buying a hurst for this very reason. I'll pay for FX4 lvl II shifter instead, I find it ridiculous that it must be magivered to work properly

Well considering how long this kit has been out.......... Yeah, not gonna happen.

Even if she's a slight leaker, it KILLS the LII shifters in regards to function.

Thanks Shane, ill have to do that this week.

And rango, I think the newer ones have no problems with this, I bought mine used is all.

Not a problem.

check this out, i believe this is what you were talking about this way right?

http://www.fordrangerforum.com/drivetrain-tech/51445-hurst-shifter-owners-issue-found.html

this is the only way id do it if i got one, just seems like alot of dickin around for me ha..

Yeah it's alot of mething around......trans needs dropped to do it. Can't get the shift rail plate off with the trans still in. If you took a look at my pics and what I wrote, I noted I was going to do what is shown in the linked thread. I plugged it and wanted to see how my idea worked. It worked. It worked GREAT actually.

Why go through the hassle when you really don't need to???

SalRanger2

Ranger Lover

ok i see, i didnt read much just saw your pic lol, ive also seen on other forums where they cut a slit in the gasket, and thats hit or miss. could be placement of the slit like you stated. do you have a pic of what the stock vent looks like? by what youve wrote it must be similar to your mod but ive never seen it

2004xlmiller

Member

i did the same mod shane has on his hurst, ill let you know how it turns out.

Fx4wannabe01

New Member

ok i see, i didnt read much just saw your pic lol, ive also seen on other forums where they cut a slit in the gasket, and thats hit or miss. could be placement of the slit like you stated. do you have a pic of what the stock vent looks like? by what youve wrote it must be similar to your mod but ive never seen it

I've done the bathroom rubber gaskets. I've done the bathroom rubber gaskets with a fat "slice of pizza removed". I've done paper and cork gaskets with a slice of pizza removed. etc... What I've done seems to be the only feasible fix without trans removal.

I don't have any pics. But I found some to show what the factory vent looks like. First pic you can clearly see a fat notch going vertically in the pivot ball.

Unfortunately with how the Hurst is designed within the gold (or gray on newer ones) cylinder, a fat notch like that is not possible. Pics above show the stock shifter stub and built in pivot ball. Stock shifter then mounts to it.

Also, you can tell what the Hurst actually does. It moves the pivot from inside the transmission up about 5" to above the transmission. Thus creating a shorter throw shift. The theory of leverage working in reverse.

2004xlmiller

Member

which bolts need loctite? the ones holding the shifter only? or all of them..

SalRanger2

Ranger Lover

i did the same mod shane has on his hurst, ill let you know how it turns out.

cool man let me know.

I've done the bathroom rubber gaskets. I've done the bathroom rubber gaskets with a fat "slice of pizza removed". I've done paper and cork gaskets with a slice of pizza removed. etc... What I've done seems to be the only feasible fix without trans removal.

I don't have any pics. But I found some to show what the factory vent looks like. First pic you can clearly see a fat notch going vertically in the pivot ball.

Unfortunately with how the Hurst is designed within the gold (or gray on newer ones) cylinder, a fat notch like that is not possible. Pics above show the stock shifter stub and built in pivot ball. Stock shifter then mounts to it.

Also, you can tell what the Hurst actually does. It moves the pivot from inside the transmission up about 5" to above the transmission. Thus creating a shorter throw shift. The theory of leverage working in reverse.

thanks for the pic and explanation. now seeing the stock vent youd think it would have some fluid coming up through but if it just needs to breath to releave the pressure, yours basically seems like the exact same but up higher

Fx4wannabe01

New Member

which bolts need loctite? the ones holding the shifter only? or all of them..

All of 'em. lol. It's a good idea to use at least blue/medium locktite on all the hardware except the forward and back arm stops. Red/heavy duty locktite for those sweethearts.

thanks for the pic and explanation. now seeing the stock vent youd think it would have some fluid coming up through but if it just needs to breath to releave the pressure, yours basically seems like the exact same but up higher

If memory serves me correctly, the fat notch is also on the other side of the pivot ball. The notches fit in those stubs inside the trans(as seen in the first pic) and that's what the arm actually pivots on. I believe that plays a roll where it allows breathability without allowing leakage. But it's been so long, like 5 years, since I've messed with a stock shifter. So memory may be a lil rusty. lol.

SalRanger2

Ranger Lover

lol i hear ya, i mean if your fix is working its what ya have to do even if the vent is or isnt thatIf memory serves me correctly, the fat notch is also on the other side of the pivot ball. The notches fit in those stubs inside the trans(as seen in the first pic) and that's what the arm actually pivots on. I believe that plays a roll where it allows breathability without allowing leakage. But it's been so long, like 5 years, since I've messed with a stock shifter. So memory may be a lil rusty. lol.

Fx4wannabe01

New Member

My hurst fix is working, the trans has been clean since i did it

Like button.

drppdyllwrngr

Member

I bought mine used. Already had the groove in it. Still leaks like crazy from the top side. I just deal with it. Soon, that trans will be out anyways.